[four_nineth]Remember when the word “hybrid” commonly referred to varieties of fruits and vegetables rather than vehicles? In addition to engines, creative engineering is resulting in other energy hybrids. These combinations of traditional energy resources with newer ones are helping us evolve to cleaner power generation. Here are a few examples of current and emerging “hybrid” solutions.

Putting lipstick on the methane pig

It’s hard to think of landfills as having redeeming qualities. Other unpleasant associations aside, they produce landfill gas (LFG), about 50% of which is methane—a potent greenhouse gas. The traditional solution to keeping methane from entering the environment has been to collect and flare it. This process releases CO2. While that’s not good news, it is an improvement over methane which is higher on the list of contributors to global warming.

But a better solution has been gaining ground in recent years. Thanks to savvy engineering and newer technologies, companies are capturing the gas and using it to generate electricity. The methane is cleaned and sent through a pipeline to a generating facility or a storage tank. SSOE helps clients evaluate the feasibility of this approach for their specific situation, and make it happen.

Carbon dioxide in the atmosphere = not good.

Improving oil recovery from domestic wells = very good.

That is the equation inspiring one oil and gas company’s project with SSOE in northern Michigan where they are capturing CO2 and using it to bring up oil in rock layers deep in the ground. The area’s power plants and natural gas wells emit carbon dioxide—a prime contributor to global warming.

The plan calls for capturing CO2 from an existing processing facility, compressing it and injecting it into the oil field at a higher pressure than that of the oil reservoir. The difference in pressure helps release oil that resists traditional extraction methods. Taking this technology one step further … the US Department of Energy and a consortium of companies recently launched an experiment to store CO2 safely and permanently in Michigan’s deep sandstone layers. Researchers believe that about half of the country has the geology capable of sequestering CO2 and that Michigan alone can provide as much as 80 billion tons of potential storage.

Emission control

Going back to the traditional power plants and the problem of their toxic emissions. In this case, the opportunity for cleaner generation of power comes in the form of selective catalytic reduction units (SCR) that work similar to catalytic converters on automobile engines. SCR systems inject ammonia into boiler flue gas and pass it through a catalyst bed where the ammonia and nitrogen oxide gas (NOx) react to form nitrogen, a benign element in the environment, and water vapor.

Biodiesel: accommodating the finicky fuel

Three years ago, a major oil company began blending biodiesel with diesel at their Minnesota terminals for a more energy-efficient fuel mix. Seems simple enough, except that biodiesel is not happy in most US climates since it needs to be kept at a temperature of 80 degrees to maintain its properties. The solution implemented by SSOE was to replace the standard tanks, pipes and pumps with insulated ones and heat the diesel when necessary to keep it at the appropriate temperature. Since the heating requires more electrical power than had been available at the terminals, those systems were also upgraded.

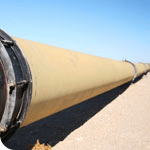

A pipeline with a new passenger

Although building a pipeline to transport fuel is a 150-year old concept by some accounts, the idea of constructing one to move ethanol across the country is just gestating. Two oil pipeline companies are looking into the feasibility of constructing a 1,700-mile, $3 billion line to carry ethanol from production facilities in the Midwest to major markets in the Northeast. Some sources estimate the daily capacity at 10 million gallons.

Transporting ethanol by pipeline will cost less than the current practice of sending it by truck or rail. In addition, a pipeline doesn’t consume fuel and generate emissions to the extent that trucks and rail cars do. Even though we’ll still use those modes to transport ethanol from the end of the pipeline to the terminals, the negative effect will be much lower. Ethanol manufacturers are hoping the study shows the financial and ecological gains will offset the $3 billion price tag.

With the 2007 Energy Bill calling for the blending of 36 billion gallons per year of biofuels like ethanol by 2022, the timing of the study couldn’t be better.

Many experts believe that life-changing breakthroughs that will solve our energy problems are years off. In the meantime, we’re diligently moving the needle toward “home-grown,” environmentally safer energy sources.[/four_nineth]

[two_nineth_last]

[box]

We want to know what you think.

[list style=””]

Did the recent 2007 Energy Bill go too far, not far enough? What will be the most difficult mandate to achieve? How will this impact your business?

[/list]

[list style=””]

Visit our website to take a 3 to 5 minute survey on the Energy Bill and be entered to win a $250 gas card or a donation to the charity of your choice.

[/list]

[list style=””]

www.ssoe.com/EnergySurvey.htm

[/list]

Take the survey now: CLICK HERE [/box]

[/two_nineth_last]