Dana Advanced Manufacturing Training Center

Owens Community College

Projects > Dana Advanced Manufacturing Training Center

Owens Community College

Design Award:

Ohio Economic Development Association | Annual Excellence in Workforce Development | 2020

Having extensive international manufacturing experience combined with nationwide higher education experience made SSOE the right choice for Owens Community College for the design of their new Dana Advanced Manufacturing Training Center. SSOE’s manufacturing facility design experts worked closely with our higher education team and the client to incorporate the latest manufacturing trends into Owen’s new real-world training center. We have worked on thousands of industrial projects and kept pace with this dynamic industry by working alongside experts in the field. The application of the knowledge we have gained resulted in the delivery of a teaching and training facility that truly reflects today’s manufacturing environments. Simulation of real-world working environments allows students to be prepared for success as they complete their courses and enter the workforce.

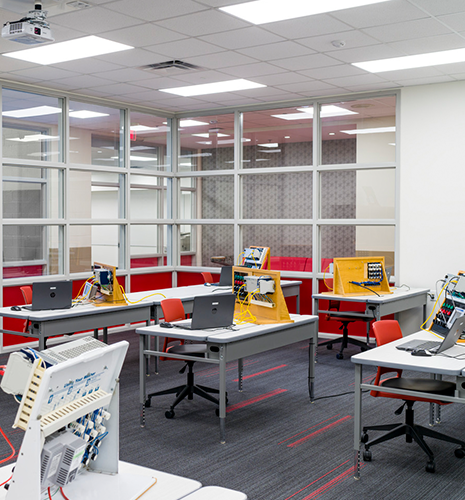

This project included the renovation of an existing high bay building into an advanced manufacturing education and workforce training facility. The facility includes seven classrooms for training and education, five computer labs, hydraulic / pneumatic lab, two mechanical labs, three electrical labs, a robotics lab, pipefitting lab, four building trade labs, group project space, storage for tools and supplies, and offices spaces. The training center houses approximately $3-$4 million worth of advanced manufacturing equipment. Also included in the project is site development to include 100-200 new parking spaces adjacent to the building. The building’s entire mechanical system was also evaluated and updated as needed to fit the project’s needs.

SSOE performed architecture, civil, structural, electrical, mechanical and plumbing engineering, fire protection, technology, communications, security design, interior design, and loose furnishings design.

Skilled Trades Training Center

Skilled Trades Training CenterAutodesk Construction Cloud (ACC) is SSOE’s enterprise-wide project delivery platform. We partner with the Autodesk Product team and have research access. Use of the AI Assistant allows our design teams, owners, and general contractors the ability to query the project specifications for quality, answers, and more rapid responses to RFIs, submittals, or issues.

SSOE has developed a proof-of-concept to use an AI Agent to act as a Master Engineer and Architect trained in SSOE’s processes, best-known-methods, and trainings. Our data structure is being remodeled to enable better use of our proprietary knowledge to train the agent on the ‘SSOE way’.

SSOE is actively piloting AI Chat large language models (LLMs) or copilots that use Natural Language Processing (NLP) to streamline both design and development tasks, transforming how our teams interact with software and each other.

By integrating chat LLM engines into platforms like Revit, we’re enabling users to prompt complex actions using simple, conversational commands. In Revit, this means automating tasks such as modeling elements, cleaning up parameter data, managing annotations and dimensions, and organizing sheets—without writing scripts. These automations and quality prompts can be shared across project teams, accelerating workflows and reducing manual effort.

Similarly, our internal Software Development Community is leveraging GitHub Copilot to expedite coding tasks. Developers can generate and refine code using NLP prompts, tapping into GitHub’s extensive Repo to move faster from concept to implementation.

Together, these tools represent a shift from traditional, expert-driven scripting to intuitive, AI-assisted automation, unlocking new levels of efficiency and scalability across our projects.

We helped our client visualize and optimize façade design for occupant comfort—long before breaking ground through the use of the Autodesk Forma tool. It allows the designer to rapidly experiment with the building’s geometry and façade design to promote sustainability, prioritizing quality of spaces and comfort for end uses, especially in extreme climates (daylighting and microclimate analysis tools) at the project’s exact geographic location, using location-specific environmental data.

Discover how SSOE is using Autodesk Forma to improve sustainability outcomes for industrial projects: SSOE Group: Improving sustainability outcomes for industrial projects with Autodesk Forma.

SSOE is utilizing Microsoft Copilot Edge and M365 to significantly enhance work efficiency and accuracy across various departments. Copilot is accessible to all staff after training. Key areas of application include using it as a writing assistant, for idea generation, document summarization and generation, research assistant, excel assistant, programming code assistant, language translations, product comparison and data analysis. Use of Copilot has become part of the everyday life of SSOE employees who have identified key ways it can help them become more efficient with their daily tasks as well as more accurate in their deliverables.

Today, 100% of SSOE employees have taken the voluntary training and have access to Copilot Edge, achieving early our October 1, 2025 goal.

We found ourselves in need of a more robust tool to enhance resource forecasting and staff assignment capabilities. Instead of waiting for the perfect tool, we’re building it. SSOE’s in-house technology team has developed and piloted a tool that aims to forecast optimal staff mix and duration for new projects against existing workload to better understand capacity and manage resources efficiently. Additionally, the tool will allow teams to identify gaps to optimal staff mix.