Battery Cell Production Facility

Confidential Battery Client

Projects > Battery Cell Production Facility

Confidential Battery Client

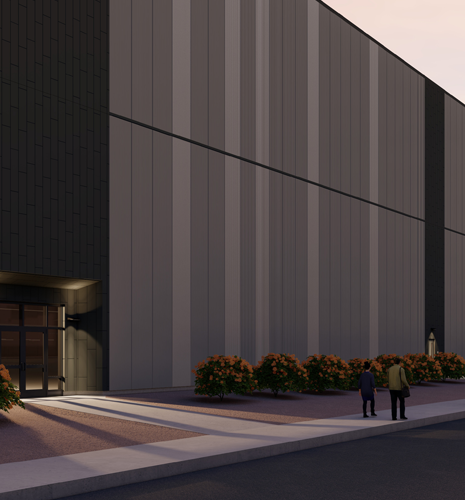

SSOE provided architectural and engineering design services for this confidential battery client’s greenfield battery cell production facility. The U.S.-based developer of battery cell technology for the energy storage and electric transportation industries, collaborated with Yates Construction and SSOE as the Design / Build team. SSOE advanced the design package to 60% completion at which point the client halted further design and construction.

The design included automated cell assembly lines, automated material movement and handling, an automated packaging line, and a pandemic-ready design to allow for safe workspaces.

The facility’s many cleanrooms were designed to maintain very low humidity requirements throughout the space, some targeting a temperature / humidity set point within the -45°C dew point range. The design used dedicated desiccant chilled water dehumidification units to dry the air, while providing space-level cooling. The rooms also utilized recirculating air handling units to allow for HEPA-level filtration and overall cleanroom pressurization requirements.

The SSOE team drew upon our unique expertise in the battery manufacturing sector to develop the designs—combining our understanding of large-scale manufacturing facilities with a technical mastery of controlled environments and process engineering.

The facility was designed to support up to 14 gigawatt hours (GWh) of battery cell production, producing nearly 60 million battery cells annually. The new facility would have production capacity to provide power for 3.2 million homes per year.

Apex 1 EV Battery Materials Manufacturing Facility

Apex 1 EV Battery Materials Manufacturing FacilityAutodesk Construction Cloud (ACC) is SSOE’s enterprise-wide project delivery platform. We partner with the Autodesk Product team and have research access. Use of the AI Assistant allows our design teams, owners, and general contractors the ability to query the project specifications for quality, answers, and more rapid responses to RFIs, submittals, or issues.

SSOE has developed a proof-of-concept to use an AI Agent to act as a Master Engineer and Architect trained in SSOE’s processes, best-known-methods, and trainings. Our data structure is being remodeled to enable better use of our proprietary knowledge to train the agent on the ‘SSOE way’.

SSOE is actively piloting AI Chat large language models (LLMs) or copilots that use Natural Language Processing (NLP) to streamline both design and development tasks, transforming how our teams interact with software and each other.

By integrating chat LLM engines into platforms like Revit, we’re enabling users to prompt complex actions using simple, conversational commands. In Revit, this means automating tasks such as modeling elements, cleaning up parameter data, managing annotations and dimensions, and organizing sheets—without writing scripts. These automations and quality prompts can be shared across project teams, accelerating workflows and reducing manual effort.

Similarly, our internal Software Development Community is leveraging GitHub Copilot to expedite coding tasks. Developers can generate and refine code using NLP prompts, tapping into GitHub’s extensive Repo to move faster from concept to implementation.

Together, these tools represent a shift from traditional, expert-driven scripting to intuitive, AI-assisted automation, unlocking new levels of efficiency and scalability across our projects.

We helped our client visualize and optimize façade design for occupant comfort—long before breaking ground through the use of the Autodesk Forma tool. It allows the designer to rapidly experiment with the building’s geometry and façade design to promote sustainability, prioritizing quality of spaces and comfort for end uses, especially in extreme climates (daylighting and microclimate analysis tools) at the project’s exact geographic location, using location-specific environmental data.

Discover how SSOE is using Autodesk Forma to improve sustainability outcomes for industrial projects: SSOE Group: Improving sustainability outcomes for industrial projects with Autodesk Forma.

SSOE is utilizing Microsoft Copilot Edge and M365 to significantly enhance work efficiency and accuracy across various departments. Copilot is accessible to all staff after training. Key areas of application include using it as a writing assistant, for idea generation, document summarization and generation, research assistant, excel assistant, programming code assistant, language translations, product comparison and data analysis. Use of Copilot has become part of the everyday life of SSOE employees who have identified key ways it can help them become more efficient with their daily tasks as well as more accurate in their deliverables.

Today, 100% of SSOE employees have taken the voluntary training and have access to Copilot Edge, achieving early our October 1, 2025 goal.

We found ourselves in need of a more robust tool to enhance resource forecasting and staff assignment capabilities. Instead of waiting for the perfect tool, we’re building it. SSOE’s in-house technology team has developed and piloted a tool that aims to forecast optimal staff mix and duration for new projects against existing workload to better understand capacity and manage resources efficiently. Additionally, the tool will allow teams to identify gaps to optimal staff mix.