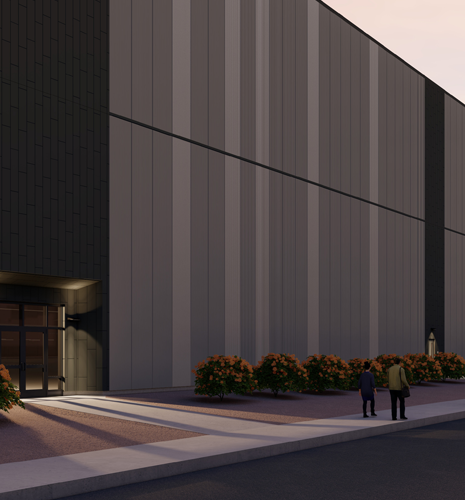

Battery Cell Production Facility

KORE Power

SSOE provided architectural and engineering design services for KORE Power’s greenfield battery cell production facility, KOREPlex. KORE Power, a U.S.-based developer of battery cell technology for the energy storage and electric transportation industries, collaborated with Yates Construction and SSOE as the Design / Build team. SSOE advanced the design package to 60% completion at which point the client halted further design and construction.

The KOREPlex design included automated cell assembly lines, automated material movement and handling, an automated packaging line, and a pandemic-ready design to allow for safe workspaces.

The facility’s many cleanrooms were designed to maintain very low humidity requirements throughout the space, some targeting a temperature / humidity set point within the -45°C dew point range. The design used dedicated desiccant chilled water dehumidification units to dry the air, while providing space-level cooling. The rooms also utilized recirculating air handling units to allow for HEPA-level filtration and overall cleanroom pressurization requirements.

The SSOE team drew upon our unique expertise in the battery manufacturing sector to develop the KOREPlex designs—combining our understanding of large-scale manufacturing facilities with a technical mastery of controlled environments and process engineering.

The KOREPlex facility was designed to support up to 14 gigawatt hours (GWh) of battery cell production, producing nearly 60 million battery cells annually. The new facility would have production capacity to provide power for 3.2 million homes per year.

Have a question regarding our services? Need assistance with an upcoming project? Send us an email. We look forward to hearing from you and will follow up soon.

© SSOE GROUP 1948-2025

Legal | Privacy Policy | CA Privacy Policy

Website designed and developed by

Raincastle Communications, Inc.

Apex 1 EV Battery Materials Manufacturing Facility

Apex 1 EV Battery Materials Manufacturing FacilityWe found ourselves in need of a more robust tool to enhance resource forecasting and staff assignment capabilities. Instead of waiting for the perfect tool, we’re building it. SSOE’s in-house technology team has developed and piloted a tool that aims to forecast optimal staff mix and duration for new projects against existing workload to better understand capacity and manage…