High Explosives Production Facility

Austin Powder Company

Projects > High Explosives Production Facility

Austin Powder Company

Austin Powder Company realized the need in their industry for increased Energetic Material (EM) supply due to the dwindling supply of demilitarized materials available. As a result, the company decided build a new chemical facility for making virgin EM. After researching and selecting key technology partners, SSOE was chosen to provide engineering, architecture, and construction management services to integrate and implement the project.

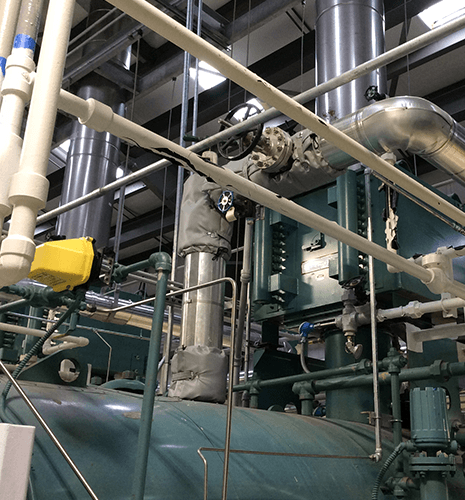

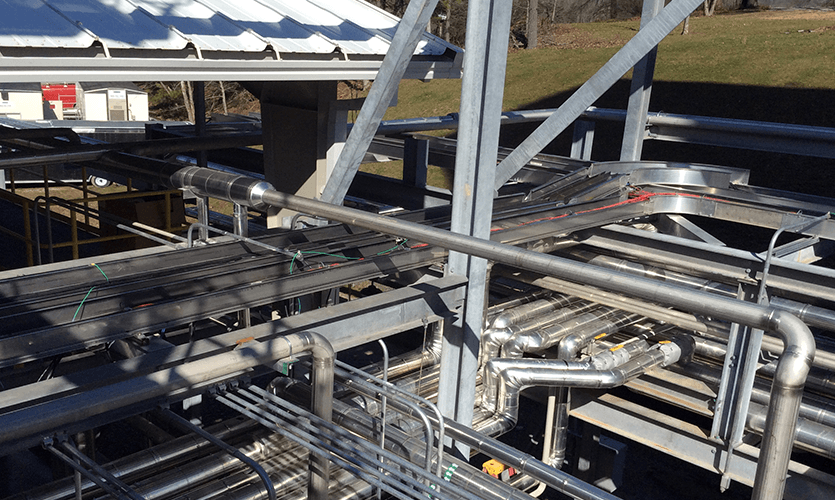

This project involved a greenfield plant for the semi-continuous manufacture of Pentaerythritol Tetranitrate (PETN) within an existing production facility. This facility performs blending and packaging of explosives, but had no chemical synthesis capability. We worked with Austin Powder and industry experts to design a safe, efficient production facility with custom processing equipment and process modules for the processing and re-use of spent chemicals and wastes.

Our team was responsible for integrating specialty process equipment from three separate process technology vendors in three different countries. Key to this integration was coordination of process controls and utilities requirements across the major vendor packages, ensuring a smooth startup and allowing for safe shutdown and maintenance during weekends, holidays, and major process upsets.

SSOE’s design scope included an EM manufacturing and packaging building; site preparation, foundation, and interconnect for all vendor modules; chemical loading, offloading, and storage; fresh and spent process water treatment; utilities to support 24/7 operation without city water or sewer access and with minimal environmental impact; rail and tank truck access for multiple chemicals; safety reviews and environmental permitting.

Have a question regarding our services? Need assistance with an upcoming project? Send us an email. We look forward to hearing from you and will follow up soon.

© SSOE GROUP 1948-2025

Legal | Privacy Policy | CA Privacy Policy

Website designed and developed by

Raincastle Communications, Inc.

Cleaning Product Manufacturing Facility

Cleaning Product Manufacturing FacilitySSOE is currently piloting software that puts a copilot engine in Revit. Using Natural Language Processing (NLP) we can prompt Revit activities such as cleaning up parameter data, annotation, dimensions, sheets and then can share and deploy automations to co-workers in different workspaces within a project. Transforms traditional process of scripts >> write the code, execute command upon an SME directing. (see transcript)…

We helped our client visualize and optimize façade design for occupant comfort—long before breaking ground through the use of the Autodesk Forma tool. It allows the designer to rapidly experiment with the building’s geometry and façade design to discover the most suitable form, prioritizing quality of spaces and comfort for end uses, especially in extreme climates (daylighting and …

SSOE is utilizing Microsoft Copilot to significantly enhance work efficiency and accuracy across various departments. Copilot is accessible to all staff after training. Key areas of application include using it as a writing assistant, for idea generation, document summarization and generation, research assistant, excel assistant, programming code assistant, language translations, product comparison and data analysis. Use of Copilot has…

We found ourselves in need of a more robust tool to enhance resource forecasting and staff assignment capabilities. Instead of waiting for the perfect tool, we’re building it. SSOE’s in-house technology team has developed and piloted a tool that aims to forecast optimal staff mix and duration for new projects against existing workload to better understand capacity and manage…