1.6 Million SF Seamless Steel Tube Facility

TPCO America

Projects > 1.6 Million SF Seamless Steel Tube Facility

TPCO America

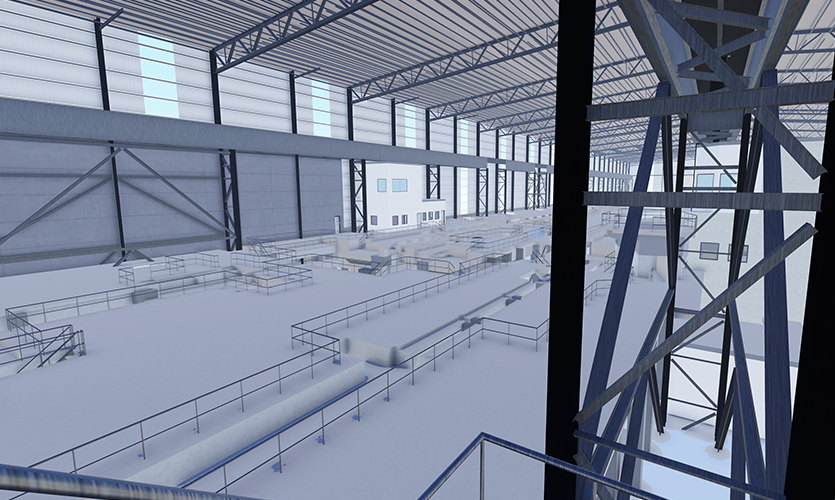

TPCO America, a manufacturer of high quality API Grade steel tube, sought to establish production facilities in South Texas in order to capitalize on the growing demand for steel tube generated by the oil and gas industry. As a subsidiary of Tianjin Pipe Corporation, China’s largest producer of seamless steel pipe, TPCO understood the importance of having American engineering and construction companies on board who are experts in designing and delivering integrated production facilities worldwide. SSOE and its construction partner, Yates Construction, were selected for their vast experience successfully delivering similar projects worldwide.

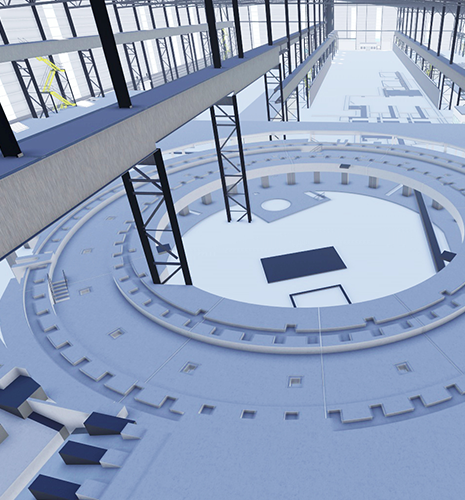

The design / build team of SSOE and Yates is responsible for the complete design of the pipe rolling / pipe finishing mill, with SSOE providing architectural, engineering, and design services for the plant, including facility and infrastructure design, facility and process utilities design, process integration, equipment installation, and construction support.

Working closely with Yates, SSOE is applying a concurrent design / build approach, which makes it possible for the team to deliver the 1.6 million SF facility on a compressed schedule. The pace of the project increases the importance of SSOE’s job to coordinate all aspects of the work with Yates.

The project site provided significant challenges, as a substantial amount of stabilization was required due to its sandy composition and the need for very stable foundation for processes. SSOE designed a piling network to stabilize the substructure and distribute the load to maintain alignment and functionality of manufacturing systems in the future. To maintain the project budget, SSOE worked with Yates to research and provide the most economical design and construction solutions for this site.

Have a question regarding our services? Need assistance with an upcoming project? Send us an email. We look forward to hearing from you and will follow up soon.

© SSOE GROUP 1948-2025

Legal | Privacy Policy | CA Privacy Policy

Website designed and developed by

Raincastle Communications, Inc.

Ground Monitoring Stations For Satellite Systems

Ground Monitoring Stations For Satellite SystemsSSOE is currently piloting software that puts a copilot engine in Revit. Using Natural Language Processing (NLP) we can prompt Revit activities such as cleaning up parameter data, annotation, dimensions, sheets and then can share and deploy automations to co-workers in different workspaces within a project. Transforms traditional process of scripts >> write the code, execute command upon an SME directing. (see transcript)…

We helped our client visualize and optimize façade design for occupant comfort—long before breaking ground through the use of the Autodesk Forma tool. It allows the designer to rapidly experiment with the building’s geometry and façade design to discover the most suitable form, prioritizing quality of spaces and comfort for end uses, especially in extreme climates (daylighting and …

SSOE is utilizing Microsoft Copilot to significantly enhance work efficiency and accuracy across various departments. Copilot is accessible to all staff after training. Key areas of application include using it as a writing assistant, for idea generation, document summarization and generation, research assistant, excel assistant, programming code assistant, language translations, product comparison and data analysis. Use of Copilot has…

We found ourselves in need of a more robust tool to enhance resource forecasting and staff assignment capabilities. Instead of waiting for the perfect tool, we’re building it. SSOE’s in-house technology team has developed and piloted a tool that aims to forecast optimal staff mix and duration for new projects against existing workload to better understand capacity and manage…