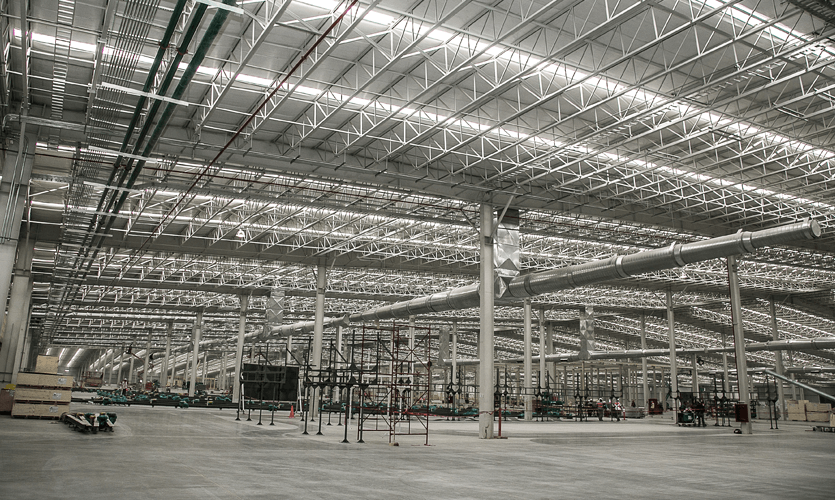

Nissan North America commissioned SSOE to provide the design of its new automotive assembly facility in Aguascalientes, Mexico. This 1.9 million SF facility is the first of three project phases planned for the greenfield site. SSOE delivered this fast-track project in partnership with Yates Construction, who served as the prime general contractor and provided at risk construction services for the manufacturing plant. The plant was designed, constructed, and placed in production within 22 months.

SSOE was responsible for the entire assembly plant layout and subsequent design of the automotive manufacturing campus. The project involved multiple buildings to be completed simultaneously, including more than 300 acres of developed land, a stamping facility, body assembly shop, paint shop, and final assembly area. Additional facilities were designed to support the manufacturing system, such as an electrical switchyard; water pretreatment, wastewater treatment, and stormwater systems; and a fire protection system, including storage tanks.