To support their North American growth in the production of automotive electronic components, Continental AG chose an EPCM approach to deliver a modern, world-class greenfield facility in central Mexico. Due to our deep understanding of what is currently driving Continental’s business, knowledge of their various facilities, ability to successfully partner on large-scale projects, and proximity to the site, SSOE was selected to serve as designer, construction manager, and owner’s agent on the project located in FINSA Industrial Park.

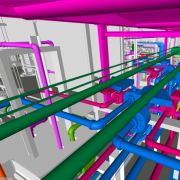

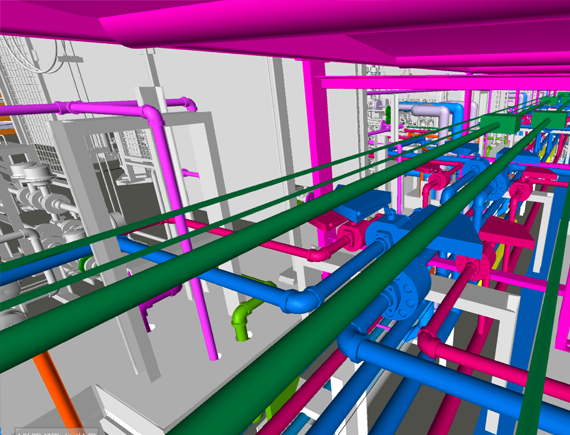

The expert design team we assembled utilized SSOE’s Revit-based platform to create a complex 3D model that was used for weekly review meetings, and can be further utilized by the client’s maintenance staff to make future updates and repairs. Although our U.S. staff served as the discipline leads, we engaged our multidisciplinary, English-speaking team in León, Mexico to heavily support the design phase and bring additional value to our client. During the design phase, our team suggested design enhancements to achieve Continental’s desired vision for the new facility—suggestions were incorporated with no

impact to the original schedule.

Building areas on the 122,000 sq. m. site totaled 24,250 sq. m. and consisted of a single story manufacturing facility and adjacent two-story office, staff area, and cafeteria. The project also included infrastructure lines on-site, internal roads, parking lots, bus drop off and truck waiting areas, as well as median connections to the park road at the boundary of the property. Design was complete within the aggressive five month schedule.