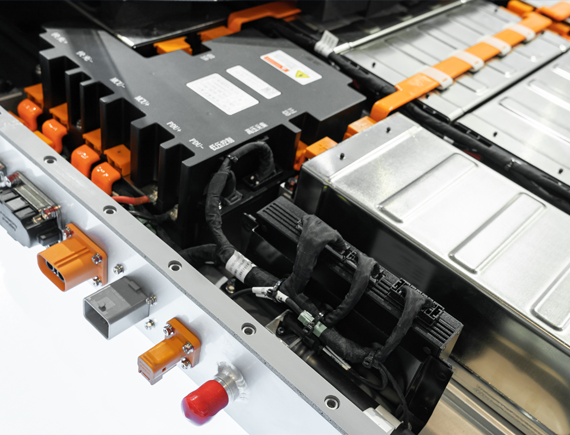

Viridi Parente is a developer of innovative battery technology that can be safely installed and operated in nearly any environment or location. The project increases the space on their 42-acre green tech campus to meet robust demand for its safe battery technology solutions. The company is working with Alberici Constructors to add 60,000 SF, expanding its total research lab, assembly, office, and production space to 180,000 SF. The expansion also integrates automation features, such as robotic welding technology and a vertical lift management system throughout the manufacturing space.

Located in a plant that was originally built by General Motors in 1923, Viridi Parente bought the plant in 2008 and renovated it to meet their needs and to better align the plant’s power usage with Viridi Parente’s goals of producing products with sustainable energy.

SSOE partnered with Alberici to provide mechanical, structural, electrical, data / fire / security, as well as fire protection engineering services on this project because of our specialized lithium-ion battery plant design expertise. Our team worked together with the client and Alberici to provide design solutions that are both sustainable and cost-effective. The newly expanded spaces include 30,000 SF for lab and assembly space and an additional 30,000 SF for increase shipping and receiving capacity. Prior to the expansion, the company occupied 120,000 SF of the campus facility with 60,000 SF of battery and machine assembly space featuring automotive-grade QA/QC, a fully integrated assembly process. It also included 20,000 SF of office and lab space, including a dedicated state-of-the-art battery testing lab for life cycle cell and module testing, thermal testing, and R&D as well as 40,000 SF shipping and receiving warehouse.