SSOE saved the client a total of $791,000 by challenging both the design and construction criteria. Our electrical approach changed the feed from the substation, the grounding at each column, and the emergency lighting source. Structurally, we saved substantial construction costs by enlarging the slab pours to minimize the slab joints.

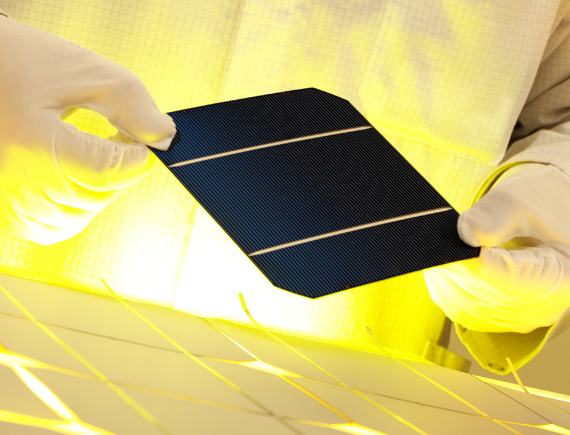

Guardian Industries partnered with SSOE to provide engineering services for an expansion at their Carleton, Michigan facility to accommodate a large float glass coating line. The expansion was located on a land parcel adjacent to the existing facility. SSOE provided engineering services for each of the two planned project phases.

The first phase included the relocation of an existing drainage system that served the township. The drainage system relocation required significant coordination with the local drainage commission and hearings held with the owners of the adjacent agricultural and residential properties. In addition to the relocation of the drainage system, the property’s wetlands had to be mitigated with the Army Corp of Engineers. Together, we determined the most efficient means to remove the wetlands from the client’s property was to purchase credits. After a series of meetings and discussions, the

plan was approved.

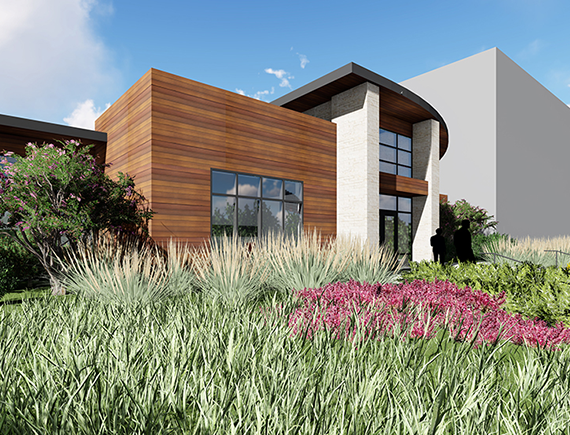

The second phase of the project was the design and construction of a 260,000 SF facility on the new property. The team sought to minimize earthwork for the new expansion, as the elevation change between the new and existing plant was significant. The elevation change required coordination with the process engineers to ensure the grade was acceptable for the transport of large sheets of float glass from the glass line located in the existing plant to the coating line located in the expansion. Design coordination was completed using 3D models between the pre-engineered building manufacturer, the coating equipment, and the facility design.

This design-build, fast-track expansion project was constructed and ready for installation of the process systems within approximately 12 months.