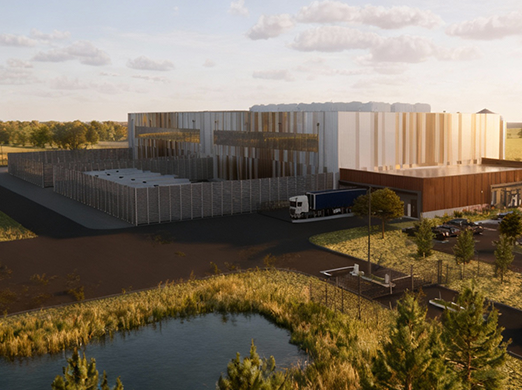

Collaborating with an energy partner, SSOE is playing a pivotal role in the development of a groundbreaking greenfield colocation data center, uniquely supported by a biomass power plant. This innovative facility, the first of its kind in the U.S., is designed to set new standards for capital and operational cost efficiency, scalability, energy performance, and sustainability. This project marks a strategic milestone for SSOE, expanding our capabilities in data center design and sustainability.

The data center will launch with an initial capacity of 2.5 MW, scalable up to 20 MW across three site locations. It supports cabinet densities ranging from 10–50 kW, with infrastructure compatibility for future AI rack deployments to exceed 100kW / rack. The facility prioritizes reliability and is engineered to meet Uptime Institute Tier III standards for concurrent maintainability and uptime.

SSOE delivered flexible design solutions that adapt to our client’s evolving needs and feedback from stakeholders. Our team provided a conceptual design framework that can be replicated across multiple U.S. locations. SSOE tailored flexible architectural and engineering solutions to specific site requirements while maintaining consistency in performance, cost, efficiency, and reliability. The project’s connection to a biomass power plant—using biowaste to generate electricity and fertilizer—underscores its commitment to sustainability. The data center will use reclaimed water from steam generation, further reducing its environmental impact.

Special design considerations include:

- Waste heat utilization: The facility integrates with a nearby biomass power plant to repurpose waste heat, contributing to overall energy savings.

- Alternative water sources: Non-potable water from a neighboring treatment facility is used for cooling and fire protection, reducing its reliance on municipal water.

- Multi-tenant flexibility: Designed to accommodate multiple endusers with varying rack densities and security needs, including liquid cooling for high-density racks.

- Diverse power strategies: The electrical infrastructure supports grid connection, potential integration with the biomass plant, and primary / standby systems using reciprocating engines and photovoltaic systems for renewable energy.

Our architectural team led the vision for the “Nature to Network” concept integrating materiality, sustainability, and future growth into a cohesive design. The façade and interior spaces were designed to create a warm, nature-inspired environment, which is also neighborhood-friendly.

Leveraging Autodesk Construction Cloud, our team captured client requirements through real-time collaboration. We developed a replicable equipment arrangement strategy supporting core data center functions while providing AI-ready infrastructure. This planning system enables seamless expansion for future upgrades, delivering long-term adaptability and reinforcing the design’s flexibility.

SSOE provided performance studies using Forma to explore solar, wind, and acoustic impacts. The team assessed façade materials for embodied carbon reductions. We conducted a capacity study to evaluate the potential generation capacity for on-site solar farm utilizing photovolatic (PV) arrays.

Using locally generated renewable energy, the data center will support energy independence and sustainability, with a 20 MW facility potentially consuming as much power annually as 16,000 homes.

Construction is expected to begin in early 2026 with the data center fully operational in 2027.