Over the past 6 years, we’ve managed to save a leading consumer products client more than $8.8 million on SSOE projects demonstrating the ever-increasing value of our partnership. They’ve utilized SSOE as their preferred A/E partner since we began providing our services to them in 2012.

The client had seldom worked with outside firms and was initially apprehensive about working with a new team. Our multidisciplinary team worked diligently and consistently to build trust within the client’s team, while providing world-class service, which has resulted in us delivering 48 projects at the client’s various processing facilities. Here are some of the highlights:

Production Capacity Increase

In order to increase the production capacity of plastic storage bags, the client entrusted SSOE with the conversion of two production lines. As this conversion involved a new product, time to market was crucial and an aggressive schedule was required. The project included the design of a vacuum and reclaim system to feed waste to the front of the production line, along with an exhaust system for new production equipment. We also provided the design of a mezzanine for the support of additional production equipment, an upgrade to the plant power supply, additional process equipment, and various building upgrades that included fire protection systems.

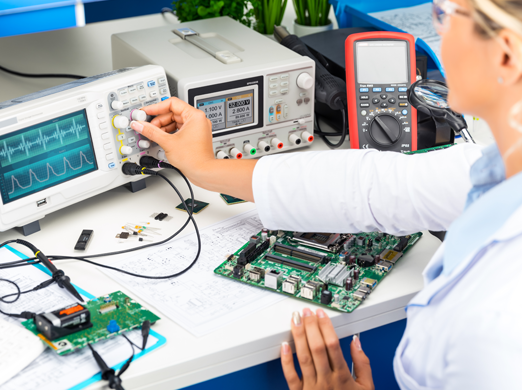

Instrument specification support and electrical upgrades consisting of a new transformer, switchgear, and electrical panels were also required. Our team was able to save the client $58,500 on this project by repositioning hangers to align with existing steel floor beams, reusing an existing roof girder to hang the bridge crane runway beams rather than installing new, and leaving the existing switchgear connected to its transformer to avoid swapping feeds with the new equipment. Additionally, we provided procurement services, construction management support, and package delivery for all SSOE-designed systems.

Innovation Solutions with Technical Know-How

Impressed by the value SSOE brought on previous projects, the client asked SSOE to design or modify various mechanical processes for multiple unique lines across several processing facilities to add new features to its plastic storage bags. Functioning as an extension of the client’s team, we worked directly with their R&D staff to design several prototype subassemblies, which were installed in a pilot line to verify functionality before full-scale design.

Based on the client’s aggressive schedule and launch date, it was evident that a traditional design / bid / build delivery method would not be effective for this project. In addition, there was a requirement to minimize downtime for all lines. We worked with the client to develop a project execution strategy that reduced the amount of downtime from 3 weeks to 2 weeks per line, providing the client more than $3 million in savings. Contractors were pre-selected and participated in review meetings early on to not only collaborate more effectively, but improve external coordination and ultimately the outcome of the project.

One challenge was incorporating more than 10 unique equipment layouts that we designed to fit into different locations within the client’s various facilities. Additionally, the layout for new equipment needed to be installed within the previously mentioned 2-week window—no small feat. We also attained a temporary project license in the location of one of the client’s facilities in order to seal required drawings and keep the project on schedule, which ended up saving the client a projected $2 million in construction package redesign fees.

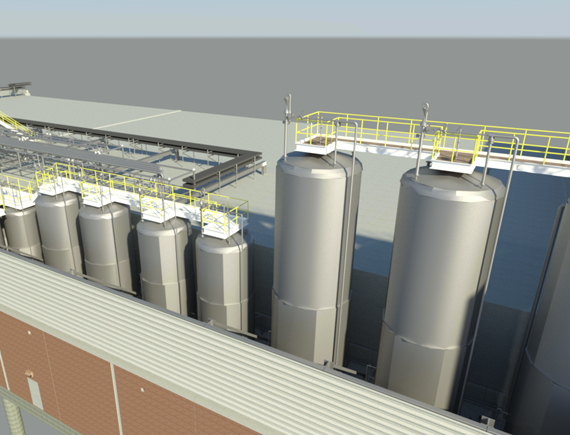

Expanding Production to Enter New Markets, with More Options

The client was looking to add three additional lines at an existing manufacturing facility to increase production capacity, expand into new retail markets, and create fresh packaging options. Our multidisciplinary team was selected to provide both facility and process support on this $25 million project—performing architectural, civil, structural, and MEP engineering on the project as well as machine design, packaging, controls and instrumentation, and process design for utilities. We were also responsible for purchasing all equipment.

During the project, we worked with the client to install temporary walls to prevent contamination and disruption of other production lines. SSOE’s in-house construction capabilities were also put to use as we helped optimize the construction bidding process for the client, assisted with procurement and cash flow management, and provided on-site field support for the duration of construction. At the peak of the project, the team consisted of more than 25 people.

The project was not without its challenges. At this particular facility, the client was implementing two very large capital projects with aggressive schedules at the same time, creating several obstacles along the way—including a contractor that was new, not only to the site, but also the client, and a modified purchasing procedure that required detailed bid packages be divided by discipline. To keep the project on track, our team assumed leading start-up and commissioning activities and was tenacious in providing the higher level of detail needed for construction documentation, meeting all budget, schedule, and staffing requirements while maintaining a level of quality the client had come to expect from SSOE. We were able to reduce the number of planned packaging lines without negatively impacting production, thus saving them more than $2 million.

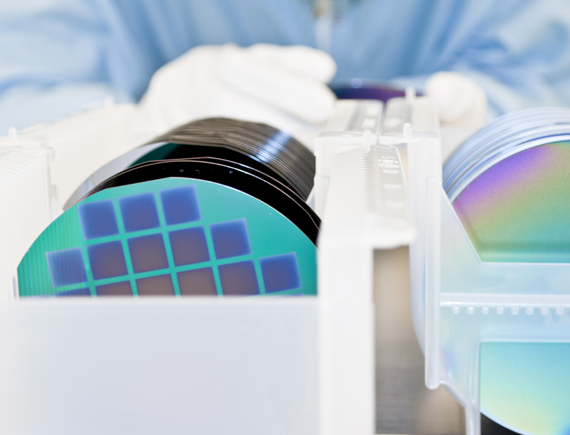

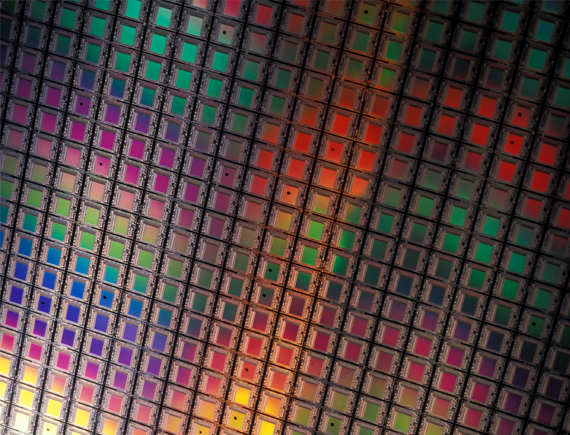

Increasing Production Output by Maximizing Technology

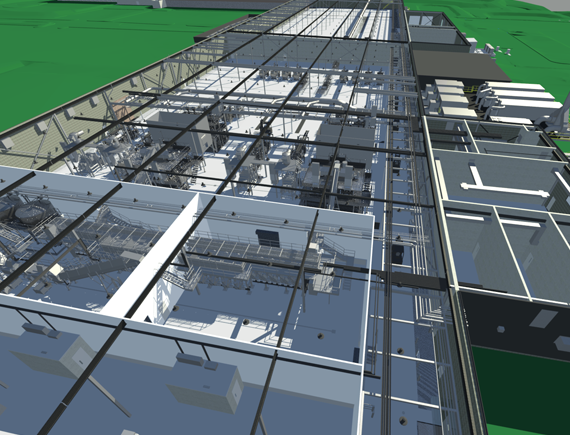

When the client set a goal of increasing its production of plastic film storage products within a multi-year period, they again reached out to SSOE for assistance. By this time, our team had worked to seamlessly integrate themselves into the client’s engineering team, assisting them with multiple key capital projects in addition to supporting a number of routine activities. Our on-site team solidified their relationship with the client, leaving them confident in our ability to help them meet their ambitious goal. Due to our positive track record and knowledge of both the client and the site, SSOE was selected to deliver this $65 million capital expansion project, providing conceptual engineering through start-up and commissioning.

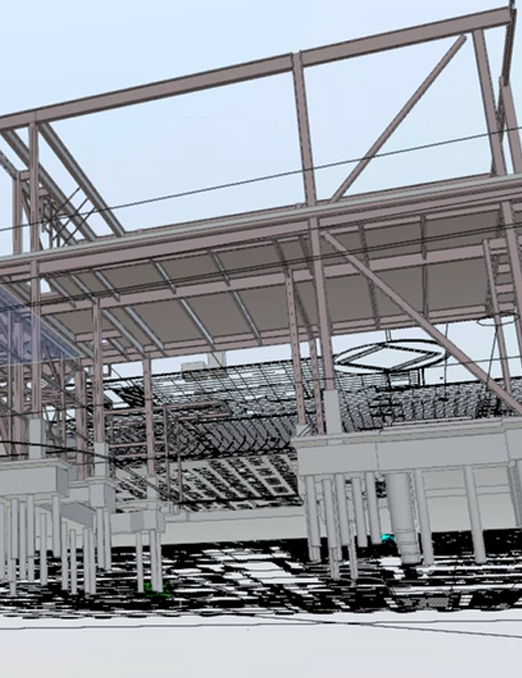

The project—designed to cGMP standards—included the design of a new facility on the client’s existing site and two identical packaging lines within: one for carton and case packing, and the other for shrink wrap and bulk packing. The process included new and innovative packaging concepts. In order to address space constraints and operator access issues, the process was designed into a Lean configuration, allowing the system to fit into the designated area while reducing overall operator travel and increasing efficiency. Notably, the SSOE-designed facility qualified the client for a local energy efficiency

program, which equated to an $170,000 credit. Our design optimizations also allowed us to eliminate confined spaces in the new facility and reduce work at heights, helping us achieve more than 180,000 working hours of injury-free construction.

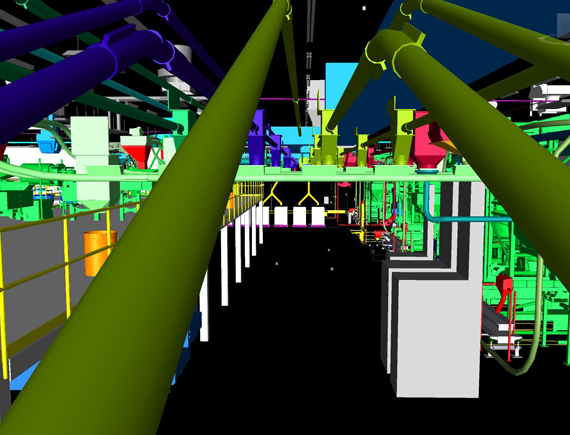

An industry leader in leveraging technology, SSOE employed reality capture, or laser scanning, to significantly improve the speed and accuracy of capturing existing field conditions. By using a long-range scanner—one of three types of scans we have the ability to perform—we not only reduced time spent conducting on-site walk-downs, we were able to create a point cloud that was referenced into a detailed 3D model, which helped avoid costly rework in the field. The resulting 3D model served as the basis for all design reviews, bringing project stakeholders together early on to eliminate hand-offs, reduce waste and cost, and compress the schedule. The approach also allowed for design changes on the fly while providing ongoing clash detection.

Giving the client a lot of credit: the SSOE-designed facility qualified the client for a local energy efficiency program for one of two packaging lines, which equated to an $170,000+ credit.