SSOE has deep experience across many manufacturing sectors. The following are examples of GE Power & Water industrial / manufacturing project experience:

- Punchline Process Improvement

- Asphalt Distribution System Analysis

- Powerhouse Backup Fuel Study

- Storage Tank Building Demolition

- 160 PSIG Steam Stress Analysis

- 400 PSIG Steam Stress Analysis

- De-Superheater Stress Analysis

- Stress Analysis HPS Steam Main

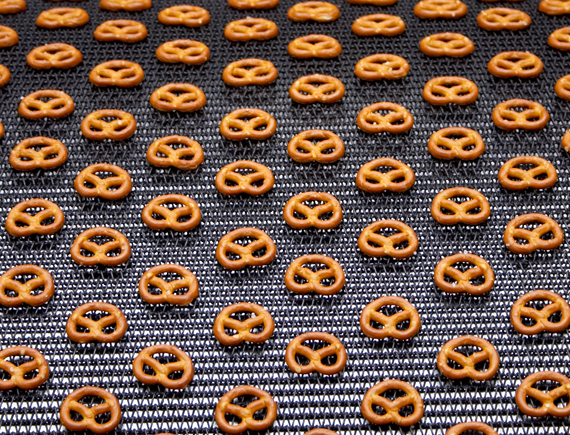

Punchline Process Improvement (2013)

Schenectady, New York

SSOE performed process analysis for the purpose of increasing product quality and throughput in the following punchline functional areas: stamping, deburring, final coating, and curing operation. Recommendations and costs were provided for replacement and improvement of the existing manufacturing equipment. The project included manufacturing flow diagrams and equipment selections.

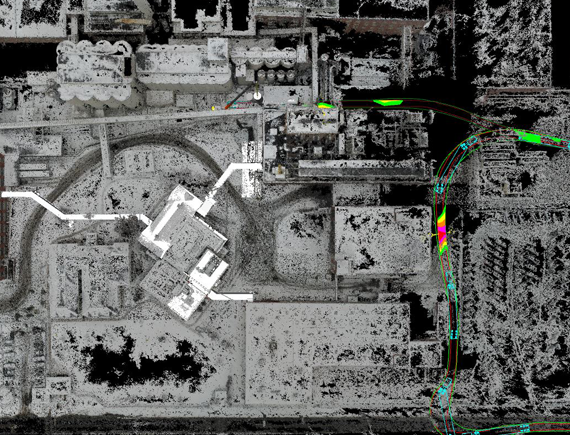

Asphalt Distribution System Analysis (2012)

Schenectady, New York

SSOE performed various engineering services for an existing asphalt distribution system in the plant’s bar shop. The project included fluid flow analysis, pipe stress analysis, pipe support system redesign and reconfiguration, project scheduling, and estimates.

Powerhouse Backup Fuel Study (2012)

Schenectady, New York

SSOE developed a study investigating various fuel options for various fuel alternates for an existing 400 PSIG steam plant. The investigation included comparison of propane air mix, natural gas, and #2 and #6 fuel oils. SSOE performed preliminary design services to help develop proof of concept. The firm also performed energy and cost analysis calculations for proof for funding.

Storage Tank Building Demolition (2012)

Schenectady, New York

SSOE provided a demolition design package for an existing abandoned asphalt storage tank and mixer. The project design included demolition and rework required for segregation from the building’s steam and electrical systems. The design required development of system understanding to minimize interruption to existing manufacturing operations. The project included design, project scheduling, and estimation services.

160 PSIG Steam Stress Analysis (2011)

Schenectady, New York

SSOE performed stress analysis per ASME B31.3 for an existing 160 PSIG system to accommodate operational temperature increase. The firm investigated field conditions to verify existing valve classes and piping infrastructure. SSOE mitigated resulting stresses through system modifications and upgrades of existing components.

400 PSIG Steam Stress Analysis (2011)

Schenectady, New York

SSOE performed stress analysis per ASME B31.3 for an existing 400 PSIG system to redesign the damaged support system. The firm provided analysis with a new recommended support scheme.

De-Superheater Stress Analysis (2012)

Schenectady, New York

SSOE performed stress analysis for a new steam loop for de-superheating per ASME B31.3. The firm worked with GE to simplify system design to expansion joints and minimize impact to the 80-year-old boiler house.

Stress Analysis HPS Steam Main (2011)

Schenectady, New York

SSOE completed an analysis of an existing 600 PSIG / 750 F superheated steam piping, 14″ line size, to confirm adequate flexibility prior to modifications performed during shutdown. Autopipe software package was used to perform the analysis and recommendations were provided back to pipe fitters prior to work.